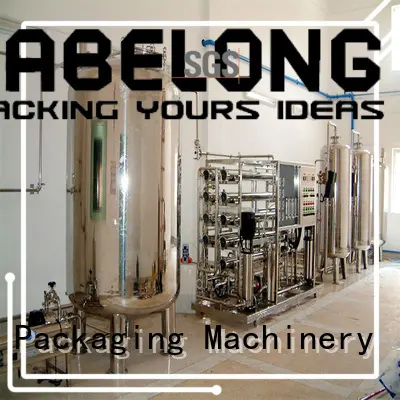

Labelong Packaging Machinery high-tech well water treatment embrane for process water

1. In the creation of Labelong Packaging Machinery [拓展关键词, the CAD software program is adopted. This software can provide a view of the piece of jewelry from all types of angles, including the inside, from the top, or the sides.

2. The product stands out for its durability. It has passed the durability testing under circumstances such as extreme temperatures (hot or cold), contamination, excessive pressures, flow, speeds, and load.

3. Workers do not have to worry that the use of this product will cause any potential dangers. It can reduce human intervention mistakes caused by the malfunction.

Company Features

1. Labelong Packaging Machinery Co.,Ltd is a firm which focuses on the production of water treatment systems .

2. Our factory has sophisticated machinery and equipment. These facilities help us to reduce reliance on manual labors and reduce raw material wastage, thereby reducing manufacturing cost and increasing manufacturing efficiency and output.

3. We have established a formal environmental protection plan. We work with clients to extend sustainability through product recovery and recycling activities and help them build sustainability into their day-to-day business. We constantly search for new and innovative ways to reduce energy consumption, eliminate waste, and reuse materials. Though these ways, we minimize our impact on the environment and develop a sustainable footprint.

1. Q: Which machine should I choose?

A: It depends on your raw water quality and your requirements for permeate water.

Usually there are three parts: pretreatment, RO machine, and post treatment. Pretreatment could be UF(ultra filtration) system, anti-scale dosing system, flocculant dosing system, disinfectant dosing system, water softener, sand filter, carbon filter, security filter etc. Post treatment could be UV sterilizer, Ozonizer, ClO2 sterilizer, etc. And maybe you need an EDI system. We will choose proper process according to your raw water quality and permeate water purpose.

2. Q: What’s your machine material?

A: For pretreatment tanks, we usually use FRP or S.S. The RO frame could be S.S, carbon steel.For pipes, it is usually S.S and UPVC. We can choose material according to your special requirements.

3. Q: What’s the control method?

A: For pretreatment, you can choose manual or automatic; for the whole system, we use relay, PLC or man-machine interface remote control.

4. Q: Which spare parts need to change regularly?

A: Filter cartridge in the security filter and RO membranes. For filter cartridge, it needs to change each 3-6 months, and for RO membrane, you need to change each 1-3 years. It depends on your water quality and how you maintain the machine.

5. Q: What’s your warranty?

A: Our warranty is 1 year. But to our experience, our machine can work 5 years before repair.

6. Q: Do you provide installation and training?

A: Yes, we can send our technician to your site for installation or training. Or you can send your staff to our factory for training.

7. Q: What’s your electricity requirement?

A: Our machine could be 380V/220V/110V, 50HZ/60HZ, 3 phase/single phase. We can do customer made products.

8. Q: What’s your machine size?

A: It depends on the capacity requirement and we can make changes according to your space.

9. Q: What’s your membrane brand?

A: We have CSM, DOW, Hydranautics, VONTRON, TORAY, etc for your choice.

10. Q: What’s the purchase procedure?

A:Customer send Inquiry -----we provide solution and quotation-----customer confirm and place order-----we send PI-----customer make first payment----we arrange production----customer make the rest payment-----we ship goods from our factory.

As our fast development recently years, all XST staffs have gone more than 15 years hand in hand, adhere to the principle of customer first, improving self knowledge, develop the technology of water treatment system and creat one after another sales miracle in this industry, our machines are used for all walks of life, such as Industrial, chemical, Medical, electrical, beverage, daily drinking, laboratory and food industries etc., not only in the field of pure water, but also backish water, seawater, waste water and so on. Besides standard products, we can also do the customized products, welcome you all to inquiry on XST company.

| Industry | Application |

| Electronic industrial | Cleaning water of electronic components (Integrated circuits, silicon chips, display tube, electrode foil |

| pharmaceutical industry | Transfusion, injections, tablets, biochemical products, equipment cleaning, etc. |

| Chemical industry | chemical recycling water,chemical products manufacturing,chemical fertilizer |

Electric power industry, Boiler Feed water | Thermal power boiler, low pressure boiler power system in factories and mines |

| Food industry | Pure drinking water, beverages, beer, wine, health products |

Seawater, brackish water desalination | Island, ships, offshore drilling platforms, brackish water |

| Drinking water | Estate, communities, enterprises |

| Others | Grey water reuse, coated glass, fine chemicals, printing and dyeing |